EOS Mechanical replaced critical chiller infrastructure at the Captain James A. Lovell Federal Health Care Center’s central plant—modernizing cooling capacity serving the entire medical campus while maintaining uninterrupted hospital operations.

About the Facility

The Captain James A. Lovell Federal Health Care Center operates as the nation’s first fully integrated federal healthcare facility, jointly operated by the U.S. Department of Veterans Affairs and the Department of Defense. This extensive medical campus provides comprehensive healthcare services to veterans and active-duty military personnel throughout the region.

The central chiller plant serves the entire medical complex, providing critical cooling for operating rooms, patient care areas, medical equipment, laboratory spaces, pharmacy, and building comfort systems. Loss of chilling capacity would immediately impact patient care, surgical operations, medication storage, and essential hospital functions across the campus.

The aging chillers had reached end-of-life status, requiring complete replacement before catastrophic failure. The VA prioritized this infrastructure upgrade to ensure reliable cooling for decades of continued medical service to our nation’s veterans.

EOS Mechanical Scope

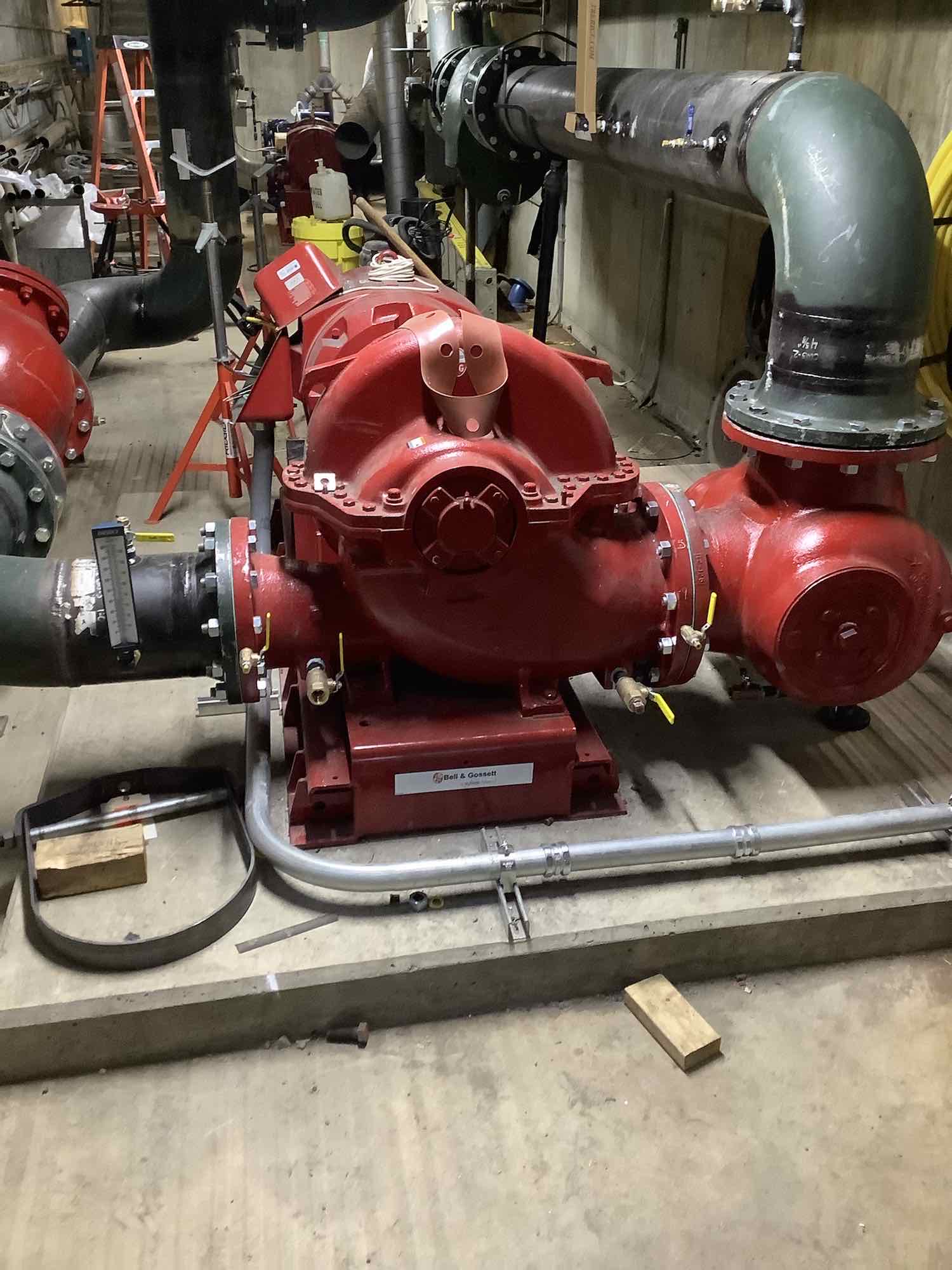

EOS Mechanical provided comprehensive chiller replacement including equipment installation, piping systems, controls integration, and advanced prefabrication—all executed within an active healthcare facility requiring continuous operations.

Chilling Equipment

- York YMC magnetic bearing centrifugal chillers - Advanced high-efficiency technology

- Magnetic bearing technology eliminating oil-lubricated components

- Significantly higher efficiency across all load conditions

- Substantially quieter operation than conventional chillers

- Reduced maintenance requirements and extended equipment life

- No oil contamination in refrigerant circuit

- Modular installation approach - Enabling replacement while plant remained operational

Chilled Water Distribution Systems

- Primary chilled water piping - Large-diameter distribution serving campus

- Supply and return mains connecting to building distribution

- Isolation valving enabling phased equipment transitions

- Expansion compensation and support systems

- Secondary pumping systems - Multiple pumps serving the new chillers

- Variable speed drives for energy optimization

- Redundant configuration ensuring continuous operation

- Integration with existing plant distribution

Advanced Technology Integration

- Controls system modernization - Integration with hospital BAS

- Chiller sequencing and optimization

- Load balancing across multiple units

- Remote monitoring and alarm notification

- Energy trending and management capabilities

- Comprehensive commissioning - Verification of all performance parameters

Construction Challenges & Solutions

Challenge: Virtual Construction and Coordination

This project involved replacing multiple chillers within an active chiller plant serving critical hospital loads. The plant contained decades of existing piping, equipment, and structural elements—many not accurately reflected in original drawings. Traditional field coordination would risk costly errors and schedule delays during critical cutover periods.

Our Solution: Laser Scanning and Point Cloud Modeling

EOS Mechanical utilized advanced 3D laser scanning technology to capture precise existing conditions:

-

Comprehensive Site Documentation

- Laser-scanned the entire chiller plant capturing millions of data points

- Generated detailed point cloud showing all existing equipment, piping, and structure

- Documented conditions more accurately than any as-built drawings

- Created baseline for all design and coordination activities

-

Virtual Construction Approach

- Modeled new chillers, pumps, and piping systems within the point cloud

- Virtually built the entire project before any field installation

- Identified conflicts and coordination issues in the model environment

- Resolved problems digitally rather than during costly field installation

-

Enhanced Communication and Planning

- Provided visual models for owner review and approval

- Communicated scope and challenges clearly to all stakeholders

- Coordinated structural supports with actual existing conditions

- Planned equipment rigging and placement with precision

- Enabled subcontractors to see exact installation conditions

Benefits of this technology-forward approach:

- Eliminated pipe routing conflicts before fabrication

- Precisely planned equipment placement and rigging sequences

- Reduced field coordination time dramatically

- Avoided costly field changes and rework

- Communicated effectively with all project stakeholders

Challenge: Aggressive Schedule with Operational Continuity

The hospital required new chillers operational by a firm deadline to avoid risking cooling capacity during peak summer loads. However, existing chillers had to remain in service until replacement units were ready. Extended shutdowns or equipment delivery delays would jeopardize patient care.

Our Solution: Off-Site Prefabrication Strategy

Using laser scan data and detailed 3D models, EOS Mechanical prefabricated major components at our fabrication facility:

-

Prefabrication Approach

- Pump packages completely assembled and factory-tested

- Piping assemblies fabricated to exact measurements from scan data

- Valve assemblies and specialties pre-installed

- Quality control performed in controlled shop environment

- Delivered to site ready for final connections

-

Schedule Advantages

- Significantly reduced on-site installation time

- Made progress while existing chillers remained operational

- Maintained flexibility if equipment deliveries were delayed

- Protected against weather-related delays

- Minimized chiller plant shutdown duration

-

Quality Benefits

- Superior welding conditions in fabrication shop

- Complete inspection before site delivery

- Fewer field connections requiring testing

- Higher confidence in system integrity

- Reduced coordination complexity on-site

-

Operational Risk Mitigation

- Kept existing cooling capacity available longer

- Minimized exposure time without backup capacity

- Reduced risk to hospital operations

- Provided contingency options if complications arose

Advanced Technology: Magnetic Bearing Chillers

The York YMC chillers incorporate magnetic bearing technology representing the latest advancement in centrifugal chiller design. Unlike traditional oil-lubricated bearings, magnetic bearings levitate the compressor shaft using electromagnetic fields.

Technology Advantages

- Elimination of Oil Systems - No oil contamination in refrigerant circuit

- Enhanced Efficiency - Higher performance across all operating conditions

- Reduced Maintenance - Fewer wear components requiring service

- Quieter Operation - Substantially reduced vibration and noise

- Extended Lifespan - Less mechanical wear extending equipment life

- Real-Time Monitoring - Advanced diagnostics and predictive maintenance capabilities

This technology provides the VA with state-of-the-art cooling equipment ensuring reliable hospital operations for decades while reducing energy consumption and maintenance costs.

Healthcare Facility Execution

Installing critical infrastructure in an operating hospital required specialized protocols:

Operational Continuity Measures

- Phased installation maintaining minimum cooling capacity

- Backup contingency plans for equipment failures

- Continuous coordination with VA facilities management

- Real-time monitoring of hospital environmental conditions

- Rapid response capabilities for emergency situations

Quality Assurance

- Factory-certified startup of all chiller equipment

- Comprehensive performance testing under load conditions

- Verification of controls sequences and integration

- Training for VA maintenance personnel

- Complete as-built documentation and O&M manuals

Results

The completed chiller plant modernization delivers:

- Reliable cooling capacity serving the entire medical campus

- Advanced magnetic bearing technology providing superior efficiency

- Substantially reduced energy consumption compared to aging equipment

- Lower maintenance requirements and improved reliability

- Seamless integration with existing plant infrastructure

- Zero disruption to hospital operations during installation

- Project completed on schedule meeting VA operational requirements

This project exemplifies EOS Mechanical’s expertise in mission-critical facility infrastructure, demonstrating our capability to leverage advanced technologies—laser scanning, 3D modeling, and prefabrication—to reduce risk and deliver complex mechanical replacements on aggressive schedules. The VA now benefits from modern, efficient chiller infrastructure ensuring reliable cooling for critical medical operations serving our nation’s veterans and active-duty service members.